Capabilities and technology

The principles of Technical Integrity are at the core of Ulbrec culture and practice. Our capability and systems are geared to meet and exceed the requirements of world leading end customers for safety and the Protection of process-critical equipment.

The principles of Technical Integrity are at the core of Ulbrec culture and practice. Our capability and systems are geared to meet and exceed the requirements of world leading end customers for safety and the Protection of process-critical equipment.

Surface Filtration Technology, Pressure Equipment Design, Materials and Fluid Flow

Ulbrec Engineered Protection solutions benefit from deep application engineering experience and design knowledge. Engineered to order Ulbrec solutions have endured a myriad of challenges including in high temperature, high pressure, cryogenic, high viscosity, highly corrosive, reversing and pulsating flow.

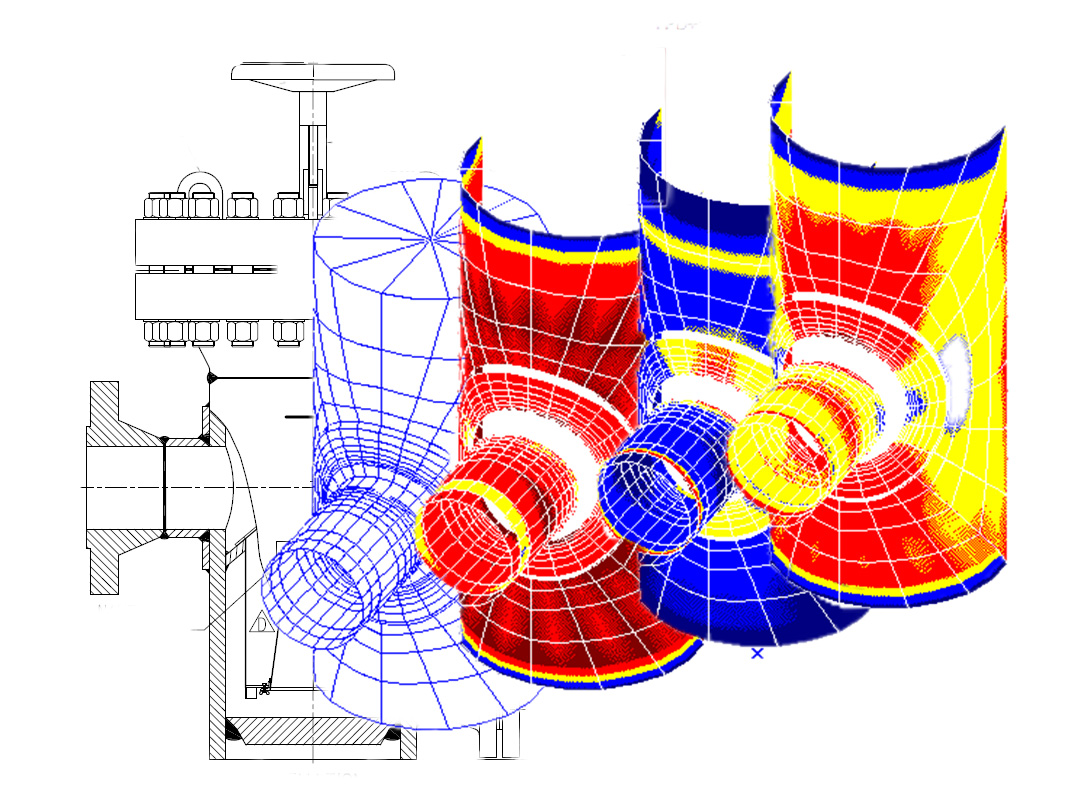

Ulbrec Designs are optimised using Best Available Technology for:

- Flow area, distribution and filtration capacity

- Guaranteed filtration level

- Energy efficiency / low pressure drop / low noise - validated designs and Computational Fluid Dynamics design verification

- Ease of maintenance

- Avoidance of resonance - modal analysis

- Mechanical integrity - field-validated products, advanced manufacturing methods and Finite Element Analysis design verification

High Integrity Manufacturing

Ulbrec solutions are designed and manufactured to comply with international and country -specific code or customer-specific requirements including design rules, calculations, materials, process control, NDE and documentation:

- Weld Procedures and corresponding welder qualifications to Australian and international standards; AS3992 and ASME IX

- Hazard level assessment to AS4343

- Design, manufacture and testing to AS1210, AS4458, AS4037

- Design verification and Worksafe registration

- ASME VIII design, ASME IX manufacturing

- Pressure piping code ANSI B31.3 and AS4041 compliance

- Vessel certification / registration by ABS, BV, DNV, Lloyds

- BS5500

- ASME U stamp vessels

- European Pressure Equipment Directive (PED) (CE mark)

- Inspection including radiography, magnetic particle and dye penetrant

- Hydrostatic pressure testing

- Positive material identification PMI, manufacturing methods and materials to comply with NACE MR0175

Screen Manufacturing Capability

Ulbrec has unique capability in manufacturing screens and filter elements from woven, perforated and multi-layer sintered stainless steels, wedge wire, duplex and super duplex stainless steels and exotic copper-nickel and copper-nickel-chromium alloys. Specialised resistance welding, GTAW, cutting and forming equipment is employed in Ulbrec's dedicated screen and cone manufacturing cells.